Tooling Solutions

JUMP TO SYSTEM

Engineering and Design | Compression Tools | Plastic Injection Molds | Tooling Secondaries |

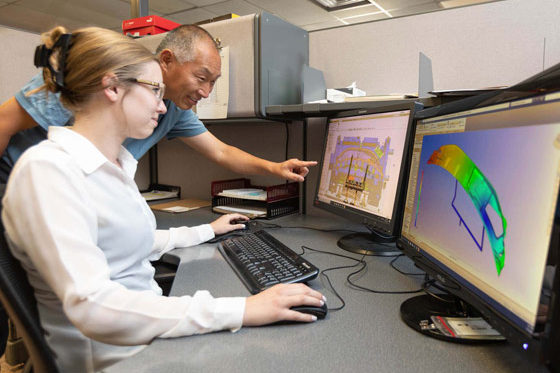

ENGINEERING AND DESIGN

Our designers and engineers at Reko use the latest software platforms to support the design and manufacturing process. Our continuous attention to detail and process optimization allows us to deliver tooling on time and on budget through our experienced team of program managers.

We utilize the following software in our day-to-day operations: Unigraphics, Moldflow, Spinfire, Lemoine, Powermill, Cimatron Data Manager (EDM).

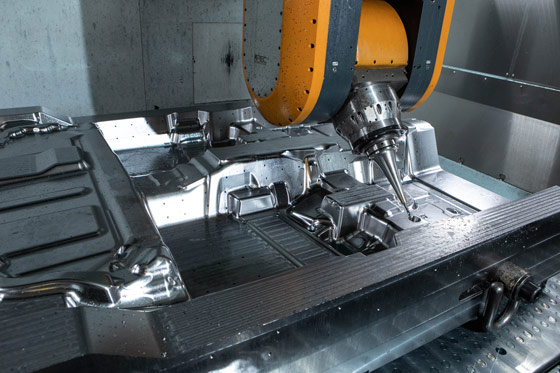

COMPRESSION TOOLS

Reko manufactures compression tooling for a variety of acoustic and soft trim applications. Our experience with a variety of materials and processes is second to none in the industry, such as the latest in RUS and fibre applications. Our large machining envelopes allow Reko to produce large scale tooling such as multiple cavity and full floor molds.

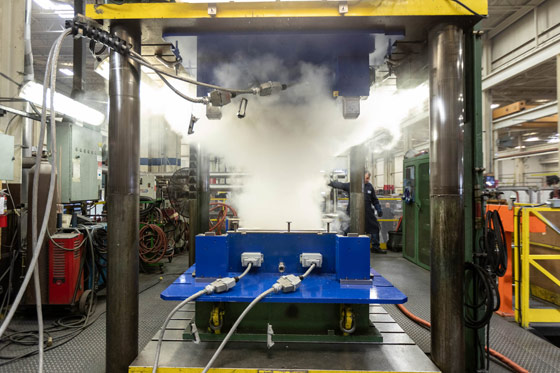

PLASTIC INJECTION MOLDS

With the highest precision and long standing experience, our plastic injection molds at Reko are designed and built by our skilled designers and toolmakers to world class standards. The molds we build typically run in presses from 750T to 4400T. We specialize in Class A surface parts for automotive interiors such as high polish and textured parts and both Interior and Exterior parts for non-automotive industries

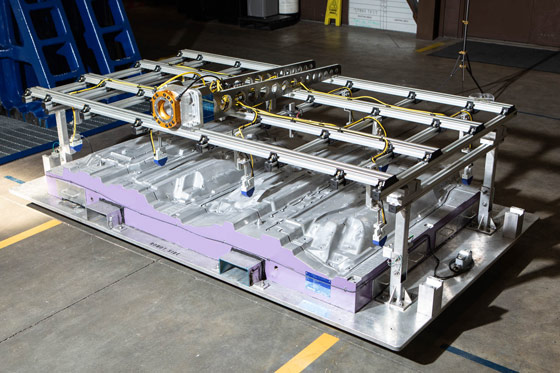

TOOLING SECONDARIES

Reko is a single source for tooling secondaries to complement our molds, all produced IN HOUSE by our experienced staff. Knowing that our customers often require a ‘one stop’ solution, we are ready to provide:

- End-of-Arm tooling for robotic part transfer

- Waterjet fixtures

- Models

- Gages

- Clip insertion fixtures

- Testing fixtures

- Assembly assist machines

Mold Repair and Support

Reko Tool & Mold is proud to offer preventative maintenance and repair maintenance of molds and tooling. Our experience in providing large mold and tool solutions as well as around-the-clock service and support has made us a leader in the industry. We are able to provide research and development techniques that are valuable for critical mold repair and support processes. Virtual tryouts allow our clients to view new injection and compression molds and services. We offer quality service at any time with our 24/7 support.